Panel Products

Our standard boards include Far Eastern Plywood, MDF, blockboard and hardboard.

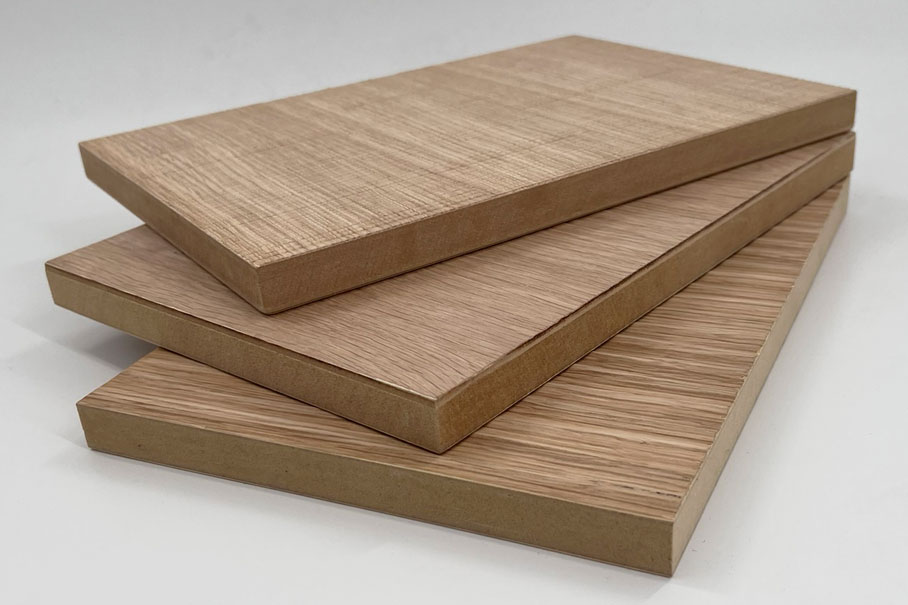

We can offer decorative MDF and plywood panels with impressive hardwood veneer finishes. Please contact us for further details. If we do not have your requirements on stock, we will always do our best to source it for you.

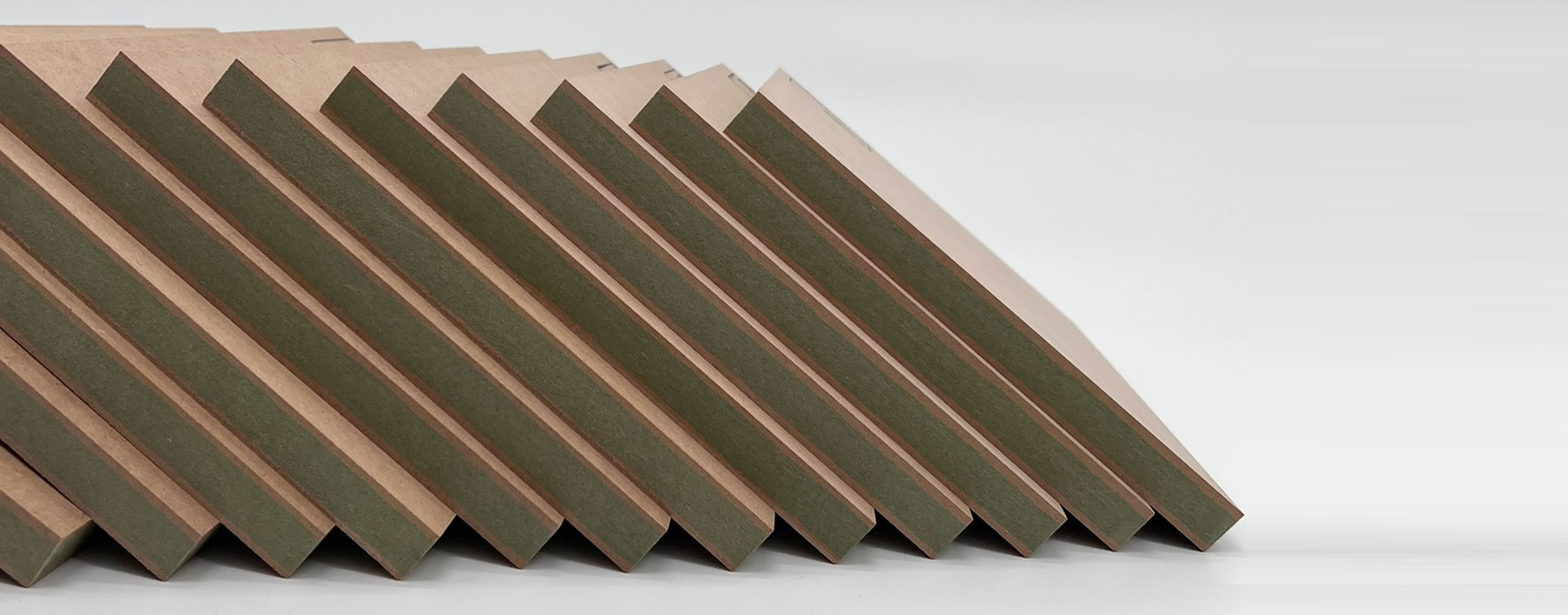

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure.

MDF is generally denser than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger and much denser than particle board. The name derives from the distinction in densities of fibreboard.

In woodworking, veneer refers to thin slices of wood, usually thinner than 3mm, that typically are glued onto core panels (wood, particle board or medium-density fiberboard) to produce flat panels such as doors, tops and panels for cabinets, parquet floors and parts of furniture. Plywood consists of three or more layers of veneer, each glued with its grain at right angles to adjacent layers for strength.

Veneer is obtained either by "peeling" the trunk of a tree or by slicing large rectangular blocks of wood known as flitches. The appearance of the grain and figure in wood comes from slicing through the growth rings of a tree and depends upon the angle at which the wood is sliced. There are three main types of veneer-making equipment used commercially:

- A rotary lathe in which the wood is turned against a very sharp blade and peeled off in one continuous or semi-continuous roll. Rotary-cut veneer is mainly used for plywood, as the appearance is not desirable because the veneer is cut concentric to the growth rings.

- A slicing machine in which the flitch or piece of log is raised and lowered against the blade and slices of the log are made. This yields veneer that looks like sawn pieces of wood, cut across the growth rings; such veneer is referred to as "crown cut".

- A half-round lathe in which the log or piece of log can be turned and moved in such a way as to expose the most interesting parts of the grain, creating a more textured feel and appearance; such veneer is commonly referred to as "rift cut." Each slicing processes gives a very distinctive type of grain, depending upon the tree species. In any of the veneer-slicing methods, when the veneer is sliced, a distortion of the grain occurs. As it hits the wood, the knife blade creates a "loose" side where the cells have been opened up by the blade, and a "tight" side.

Plywood is a sheet material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which includes medium-density fibreboard (MDF) and particle board (chipboard).

All plywood's bind resin and wood fibre sheets (cellulose cells are long, strong and thin) to form a composite material. This alternation of the grain is called cross-graining and has several important benefits: it reduces the tendency of wood to split when nailed at the edges; it reduces expansion and shrinkage, providing improved dimensional stability; and it makes the strength of the panel consistent across all directions. There is usually an odd number of plies, so that the sheet is balanced - this reduces warping. Because plywood is bonded with grains running against one another and with an odd number of composite parts, it is very hard to bend it perpendicular to the grain direction of the surface ply.

Smaller thinner plywoods and lower quality plywoods may only have their plies (layers) arranged at right angles to each other, though some better-quality plywood products will by design have five plies in steps of 45 degrees (0, 45, 90, 135, and 180 degrees), giving strength in multiple axes.